Solvaro is known for producing complex components with demanding geometric, deep-drawn shapes. Customers appreciate Solvaro’s high quality standards, which are ensured, among other things, by precise and continuous testing of geometric dimensions such as component dimensions, shape and position.

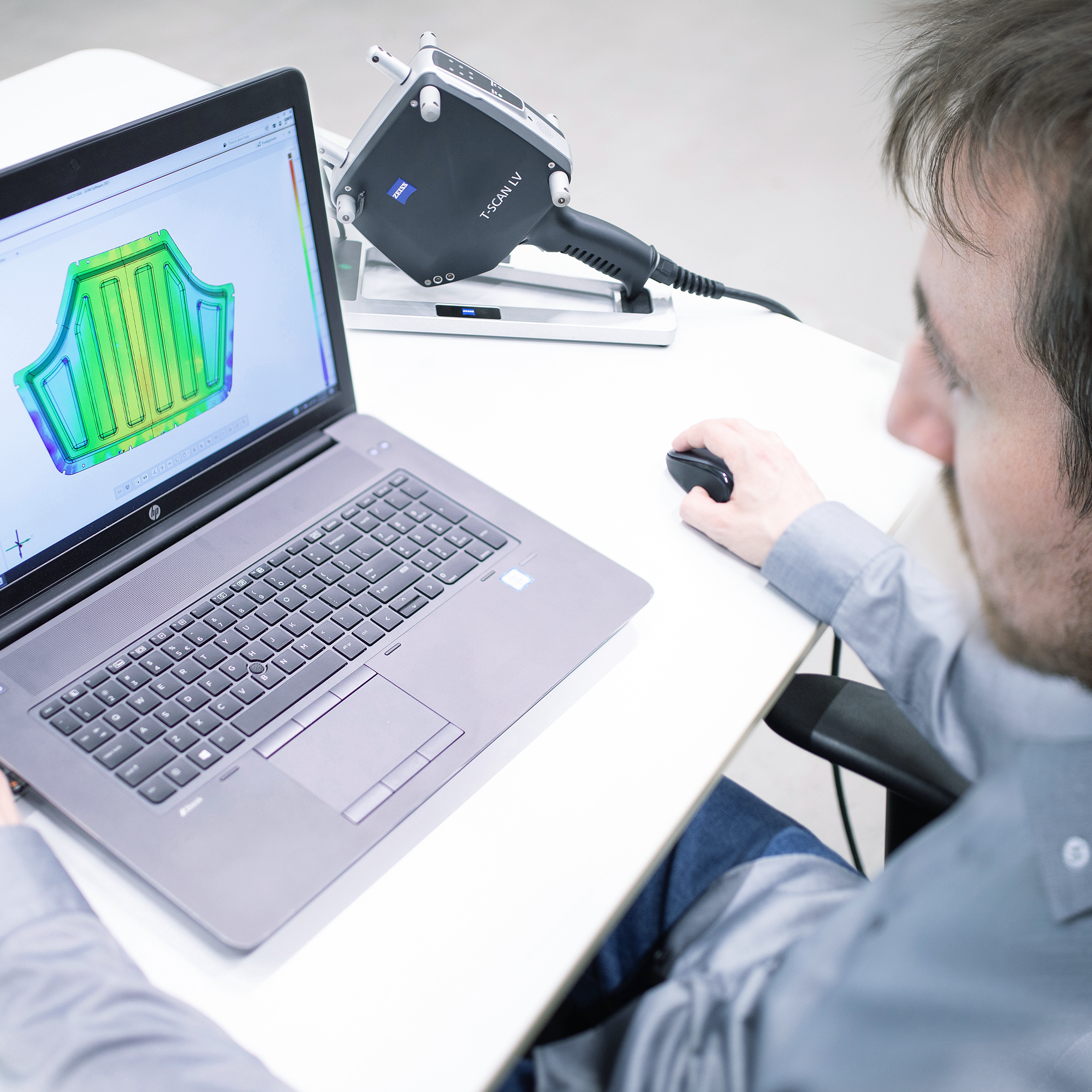

With the investment in the new T-SCAN measuring device by the leading measurement technology specialist Zeiss, Solvaro now also offers these measurements in-house. The advantage from the customer’s point of view: a significantly more efficient quality control process and short distances for intermediate inspections. Solvaro can continuously inspect complex deep-drawn components with the T-SCAN measuring device and thus react immediately to deviations. The result: High-precision components with short production times and the highest quality standards.

Watch our 3D scan video here.

3D measurements with non-contact laser technology

Compared to conventional, tactile measuring methods, the non-contact 3D measuring technology scores with a particularly intuitive, fast and simple application. The T-SCAN measuring device allows Solvaro to carry out comparative measurements and reverse engineering of complexly shaped components reliably, precisely, and efficiently.

Until now, these measurements had to be carried out either by external partners or with the help of tactile measuring techniques.

Step by step to the 3D model

The measurement of complex 3D geometries is possible with the T-SCAN measuring device without any component preparation at all. The hand-held laser scanner is simply moved over the surface of the component at a distance of about 15 cm. The laser device works at a data rate of 210,000 points per second – the captured data points are imported into the Zeiss software. The optimised data is then available in the user-friendly 3D software GOM Inspect. The result can be seen directly on the screen: A high-precision 3D model that allows, for example, the comparison of components with CAD models.

The benefits at a glance

- Optimum quality assurance through continuous component testing

- Short ways for intermediate inspections

- Reduced production time thanks to efficient in-house measurement

- Highest measuring precision thanks to advanced laser technology

- Suitable for a wide range of surfaces and applications

YOUR CONTACT

OUR PRODUCTS IN APPLICATION

THESE ARTICLES MIGHT ALSO INTEREST YOU

YOUR CHANCE: A METAL EXPERT TAILORED TO YOU

SIGN UP FOR THE SOLVARO NEWSLETTER

Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.