Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

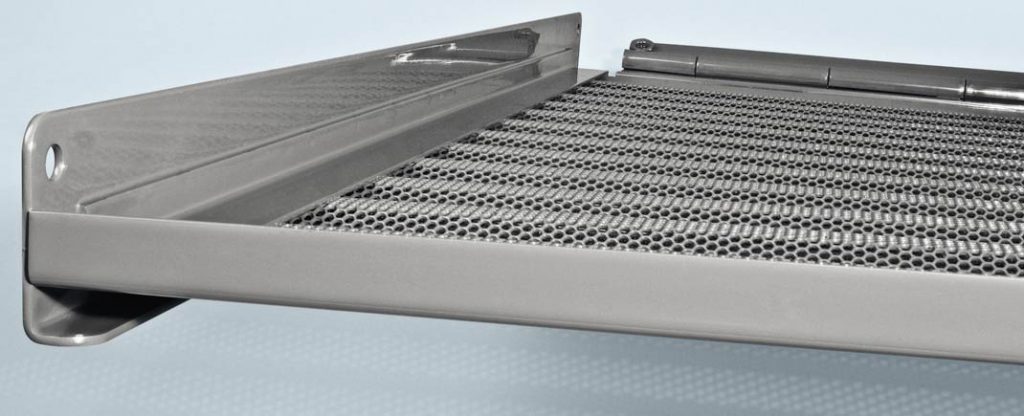

Anyone who installs coated metal parts knows the myriad of influential factors that go into achieving high-quality rust protection. And it’s even more complex when parts are perforated. After all, perforated sheet metal behaves differently than solid material and raises a whole new range of specific challenges.

More holes call for more edge coverage

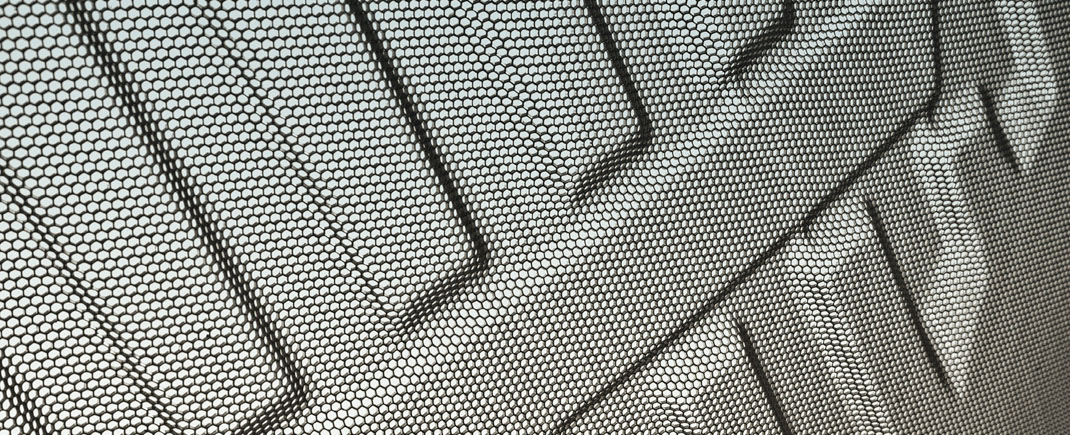

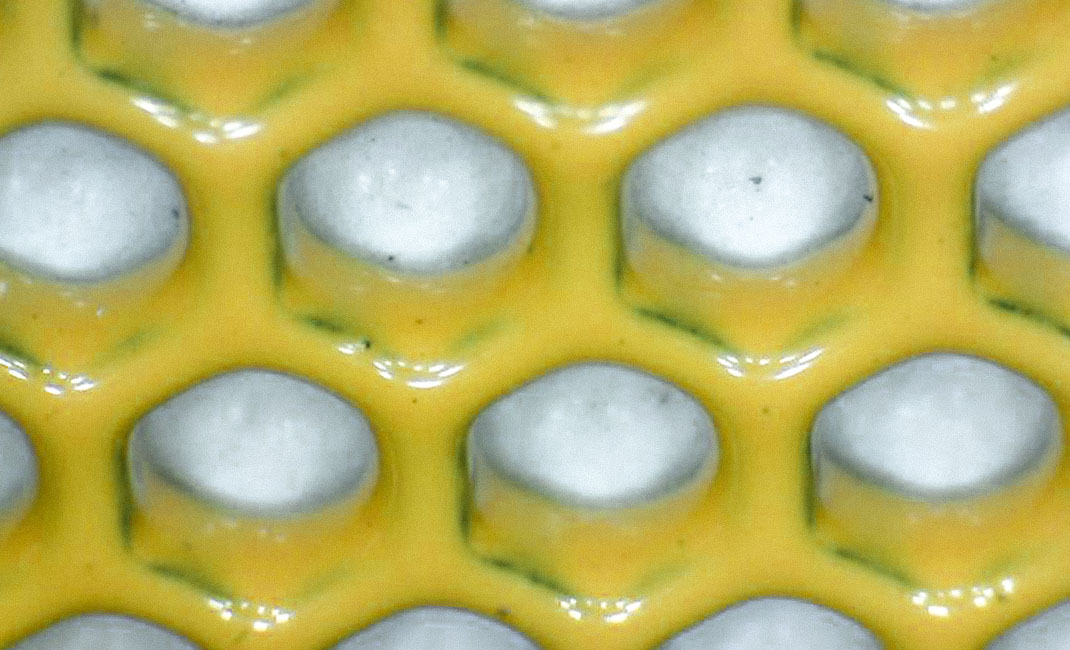

There are 184,000 holes in one square metre of metal component with hexagonal perforation. The areas between the holes are just 0.5 mm wide. An open area of this magnitude makes it immediately clear that sheet metal has different surface properties than a non-perforated component. For surface engineers, the specific issue is that the holes can be easily obstructed. To much paint at one point is a problem. Too little at the hole edges is another. Rust protection can only be assured when there is sufficient edge coverage – but at the same time, the functionality of the holes themselves must not be affected.

More distinctive knowledge brings more added value for all

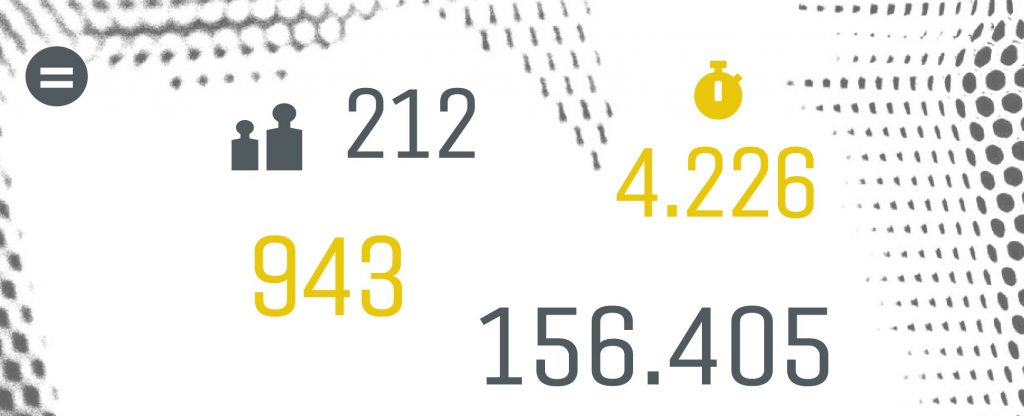

Whether it’s knowledge of the raw materials, the production process, surface methods, paint or powder manufacturers and test procedures for quality assurance, we’ve taken a proactive approach to rust protection. Our ventilation grilles and engine bonnets for agricultural and construction vehicles and buses must meet high requirements. The path to an optimal result first makes its way through a real ‘jungle’ of standards, including factory standards, DIN standards, and various assessments and tests – but who needs what And which requirements and test results are relevant for whom? To gain more insight here and an easier overview, we’ve collated comprehensive independent experiences, like the self-conducted testing at the Institute of Surface Engineering (IFO) in Schwäbisch Gmünd, Germany. The new information was documented in an interactive table, which provides an at-a-glance overview of what is possible with perforated metal and where its limitations lie.

The solution at a glance

- Testing and filtering of standards for coating metal parts

- Support during the quality assurance process

- Coordination and close collaboration with coating partners and customers