Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

Two perspectives on introducing the automotive standard

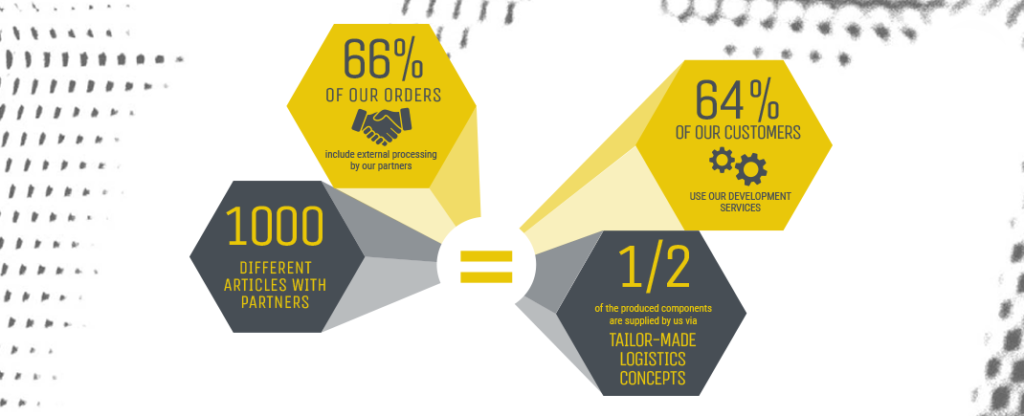

As a specialist for perforated metal components, Solvaro is a crucial key supplier for its customers. The company supplies OEMs of construction and agricultural machinery, buses and trucks with high-quality ventilation grilles and engine hoods.

In developing its metal components, Solvaro maintains a close partnership with its suppliers on the one hand and its customers on the other. With a committed customer focus and its partnership-based development approach, Solvaro knows the industry-specific requirements for perforated metal components in the vehicle engineering process down to the tiniest detail.

The declaration of intent by Solvaro’s executive management to introduce a certified quality management system according to the automotive standard IATF 16949 once again underscores the company’s customer- and industry-oriented approach. With the introduction of the QMS standard, the company aims not only to meet the demand for IATF 16949 certification set forth by many OEMs and tier 1 suppliers, but also to put the company’s ongoing improvement process through its paces.

External support for the introduction of the automotive standard

Certification according to IATF 16949 is predicated on a demanding introduction process in which existing processes are put to the test and optimised, and new methods are introduced.

To be optimally prepared for this ambitious undertaking, Solvaro has brought in some outside support: Dr. Michael Zöller of Würzburger Umwelt- und Qualitätsmanagement Consulting GmbH (WUQM) will be supporting the company in its introduction of IATF 16949 with his expertise as a QM auditor.

Dr. Zöller is here with us today alongside Solvaro Managing Director Gerhard Bullinger – in this interview, we take advantage of the opportunity to look at the QMS introduction under IATF from an internal and external perspective.

Question: Mr. Bullinger, Solvaro has declared its intention to seek certification under IATF 16949. What moved the company to take this step?

Bullinger: The Solvaro company stands for solving problems – solvere comes from the Latin and means “to solve”. So a solution-oriented style of work is part of our DNA. And the easiest way to solve problems, as we all know, is to prevent their emergence in the first place. This principle is baked into our daily work – which means we have already largely internalised the continuous improvement of our processes.

So the demand for IATF certification from our customers is a logical next step for us in our development. What’s particularly important for us in that process is that every improvement yields a concrete benefit for the customer and that we’re not just blindly going by the book. Every process and every improvement has to achieve results and not just be done for its own sake.

With the introduction of the IATF standard, we are creating a shared understanding of quality along the entire value creation chain. The fact that we are already certified under ISO 9001 simplifies the introduction process.

Question: Dr. Zöller, help us understand this: In what ways does IATF 16949 expand on the ISO 9001 standard?

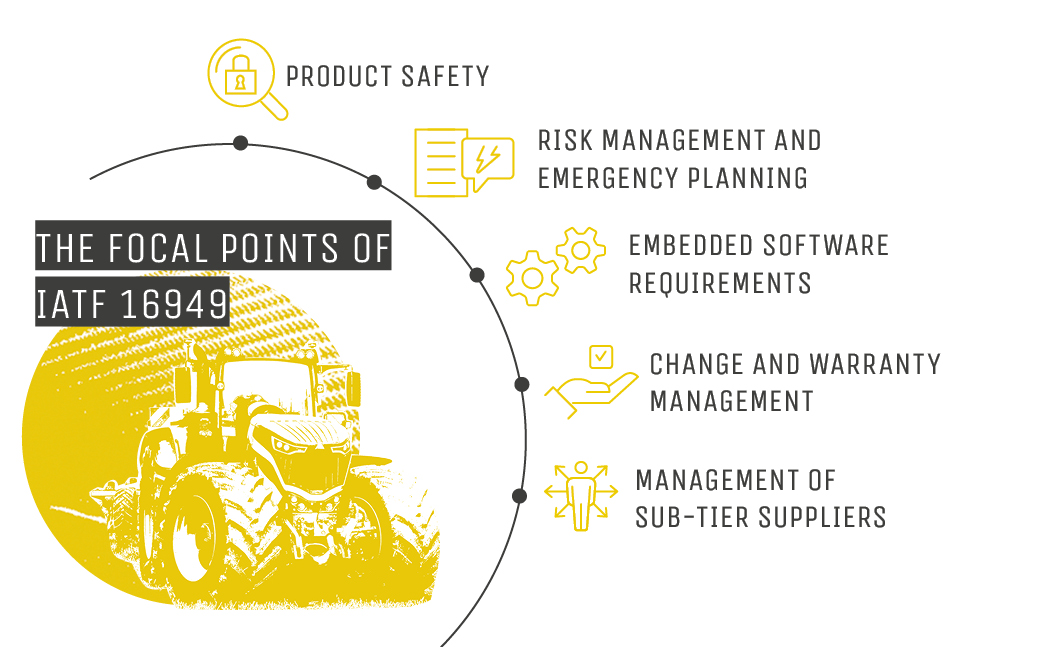

Dr. Zöller: IATF 16949 is an industry-specific requirement from carmakers to their supply chain. The IATF is 100% based on ISO 9001:2015 and places much more stringent requirements on the organisation compared to ISO 9001. Rules that were relaxed in the latest revision of ISO 9001, such as forgoing the QM manual, have been retained in the IATF. Over the medium term, the IATF is intended to penetrate the entire supply chain down to tier N.

Beyond the more comprehensive requirements specification of IATF 16949, certification according to IATF is the market entry permit that makes it possible to remain a partner to the automotive sector over the long term.

ISO 9001 vs IATF 16949

IATF 16949 extends the industry-neutral requirements of quality management standard ISO 9001 with additional requirements for the automotive industry. IATF 16949 should therefore be seen as a supplement to ISO 9001 and can only be applied in conjunction with that standard.

,Question: Mr. Bullinger, what do you view as the concrete advantages of certification under IATF 16949?

Bullinger: In addition to the aforementioned prevention approach, for us it’s critical to establish the standard as an internal control mechanism for quality standards and a guide for the continuous improvement of processes. Many customer requirements are already incorporated in the standard by default, so it helps us build trust with our customers and reduces the eher zeitlicher Aufwand, nicht kosten z.B. time oder intensity of customer audits on both sides. It also greatly simplifies the onboarding process with new customers.

Question: You talk about risk detection as an advantage of the standard. Can you explain that to us using a concrete example?

Bullinger: A good example are components that are also formed by us, in most cases using the deep-drawing process. The identification of potential sources of error at the outset of the project is essential in this context. We are working here with cost-intensive tools that cannot be modified quickly or cheaply. This applies in particular to deep-drawing tools: If an error is not anticipated in good time and is only detected after production of the tool or perhaps only after it is in series production, massive costs into the six-figure range can be the result. And the delays are also large – manufacturing high-quality tools takes time.

Question: Dr. Zöller, how do you approach the introduction of a QMS according to IATF 16949 for a supplier like Solvaro? What are the first steps?

Dr. Zöller: Solvaro has had a well-functioning QM system for many years. The introduction of IATF 16949 begins with a gap analysis intended to identify any divergences from the requirements in the standard. Based on these divergences, work packages will be defined that need to be executed step by step. The employees are the key to this process: Without the team, the requirements cannot be integrated in workflow management on a long-term basis. This must be carried out with the aid of practical workshops in which the need for the change is explained to the employees and ways are found to close the requirements gaps in the everyday work of the company.

Question: What do you see as the biggest hurdles on the way to successful IATF certification?

Dr. Zöller: The biggest hurdle is certainly the long-term implementation of the requirements in workflow management. The organisation should not leave the quality management officer alone with this task. Due to the distance between the locations, the language barrier and the pandemic-related travel restrictions, it is difficult to implement the requirements quickly with the team. The QM officer cannot do that alone, nor indeed is it even their task to do so. Everyone is involved in quality management and everyone has to do the work. If that doesn’t work, the project is not viable.

Another aspect is that such change projects are always in addition to daily work. If not enough time is made available, that can draw out the project significantly. For the quality management to continue working, a certain amount of overhead is required. Without that, the requirements of the IATF cannot be maintained within the organisation.

Question: How long does the entire certification process take in order to integrate the specifications of the standard into the company on a lasting basis?

Dr. Zöller: The duration of the project always depends on what resources are made available for the project by management. The uncertain situation during the coronavirus pandemic was certainly not helpful. It is still not possible at this point to make a reliable statement concerning when the project can be completed.

Also, a QM project does not end with the certification. Requirements change all the time, the technology continues to advance, the market continues to develop, so the organisation must also continue to develop and improve. Quality management provides the tools that make it possible to remain a major player.