Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

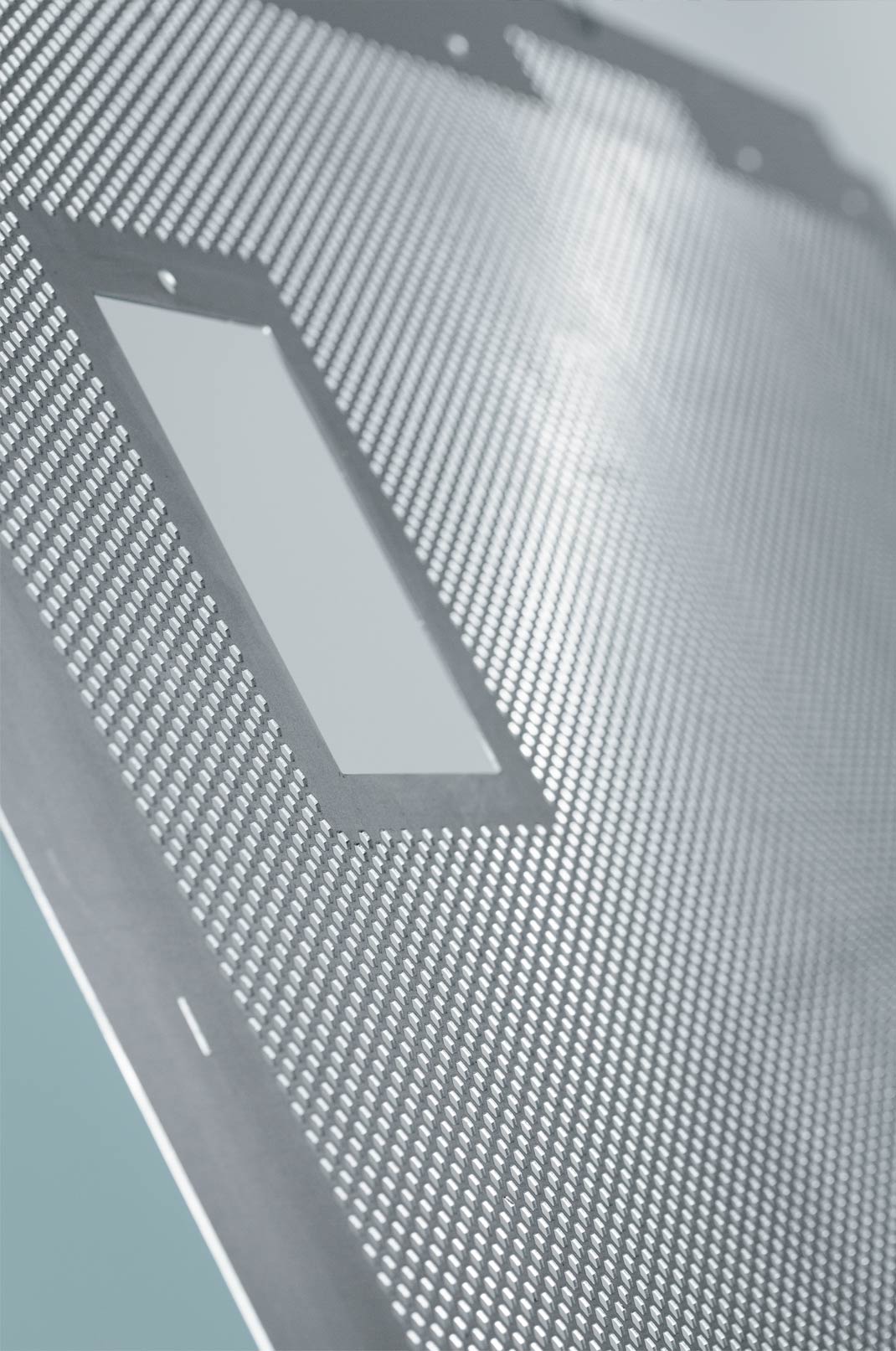

Our parts delivery doesn’t finish at the customer’s incoming goods door. We make it our responsibility to also support our customers as best we can with the next steps in the manufacture of the end product. For example, we developed special packaging for the shipment of our customer Zollner’s server cabinet doors. This packaging is in line with Zollner’s internal requirements and makes it possible for items to be delivered directly to the finishing machine on the production line without the need for any unpacking or repacking.

Upright rather than laid flat – stillages rather than pallets

Due to their dimensions, server cabinet doors tend to be packed and laid flat on pallets for shipping. Measuring more than 1,858 mm in length and at widths of 320.2 mm and 578 mm, this would also be the easiest way to pack Zollner’s two-part cabinet doors. However, the premises where Zollner subsequently works on the cabinet doors aren’t big enough to accommodate pallets – the doors and corridors to the production line are too narrow. Repacking the doors there costs time and money. So we came up with the following solution for Zollner: the components are packed and stacked upright at SOLVARO in a stillage (800 mm x 1,200 mm). This is narrow enough for it to be moved around at Zollner and can easily be moved to its rightful place using a pallet jack.

Customised reusable packaging for 15,000 doors

Here’s how it works: the stillages are specially prepared in order to prevent damage during shipment. Spacers made of wood prevent metal from rubbing against metal. The individual components are additionally kept apart with cardboard packaging. There cannot be any scope for movement, so the stillages have to be completely full when shipped, each holding 42 components. The order quantities have therefore had to be adapted to this delivery method. The specially prepared stillages are in permanent circulation between the two companies. To date, more than 15,000 server cabinet doors have been securely delivered in this way for finishing.

The solution at a glance:

- Alternative packaging and dispatch method for server cabinet doors

- Space-saving upright shipment in specially prepared reusable stillages

- No repacking necessary at the place of delivery

- Direct delivery to the finishing location