Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

You need the right equipment and a diverse range of high-quality tools to produce perfect metal components. Special tools are needed particularly in the field of sheet metal processing, be that for cutting, punching, lasering, chamfering, deburring or deep-drawing parts. The knowledge needed for the construction and maintenance of these tools calls for a wide spectrum of specialist expertise.

Punching tools: the extra polish for all-important workhorses

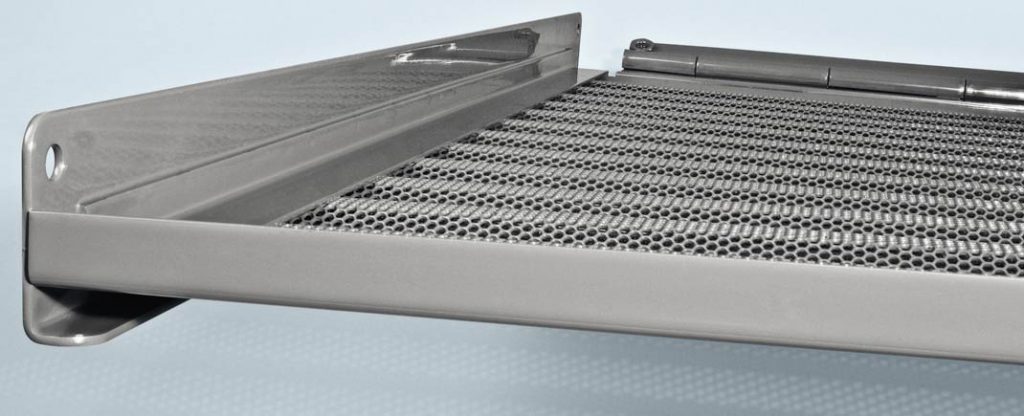

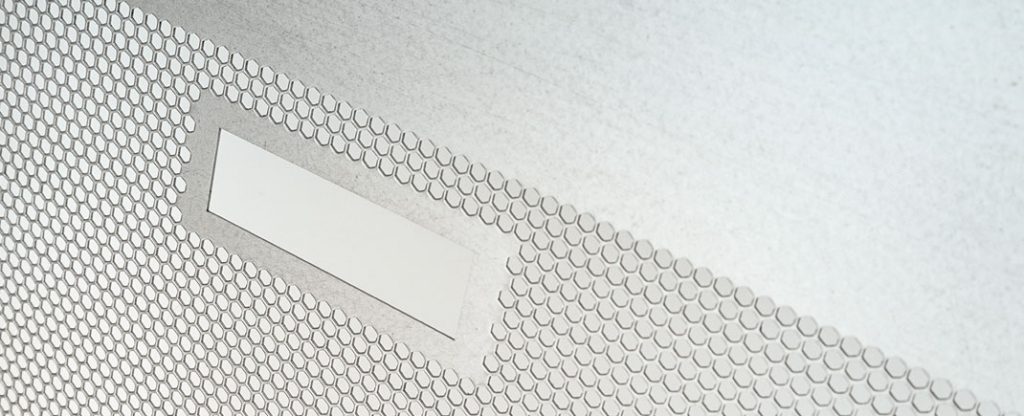

Most of our products are either fully perforated or feature perforated sections. For this reason, an extremely extensive range of punching tools forms the foundation of our tool inventory. We have more than 1,500 punching tools at our disposal: from tools that create round holes, oblong holes or our speciality, hexagonal holes. The tools have to meet special requirements. They are often used over very long periods of time and exposed to high forming pressure. Constantly maintaining and regularly polishing the tools is important to preserve the quality of the holes they produce. The exact moment a tool is ready for a pit stop in our in-house workshop can vary depending on the thickness of the base material and the shape of the hole. Missing the right moment might entail quality problems such as a deviation of the hole from the tolerance or increased formation of burrs. Our experts recognise the necessity of maintaining and polishing the tools and act quickly and with precision. They have also developed our own special polishing tool for the hole punch of our hexagonal tools, which ensures especially high-quality results here.

Deep-drawing tools: sophisticated engineering for powerful heavyweights

Aside from perforating parts in quick succession, tools also play a very special role in another area of component forming: deep-drawing of completely or partially perforated metal parts. The deep-drawing tools we use are true heavyweights at up to ten tonnes, but even they still require a special touch during manufacturing and use. Very close attention is paid to their engineering and development. Once manufactured, these giant heavyweights cannot be changed easily – and with manufacturing costs in the six-digit range, changes at this point are considerably undesirable. The trick, then, is to anticipate how the perforated sheet metal will behave during deep-drawing, in order to avoid having to make changes to the tool after the fact. At the moment, computer simulation is only possible to a limited extent here due to the enormous amount of data generated for perforated parts – this is where our wealth of experience and expertise really shines. Expertise instead of simulation, and collaboration with strong partners means that we can always come up with the optimal result. We already have 212 tonnes of precision deep-drawing tools in our inventory, which have been used to manufacture 943 different items.

The solution at a glance:

- Over 1,500 different punching tools

- In-house workshop for tool maintenance

- Special expertise for polishing hexagonal tools

- Engineering and development of deep-drawing tools with experienced partners

- Practical approach and extensive knowledge in the manufacturing of tools

- Inventory includes deep-drawing tools weighing a total of 212 tonne