Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

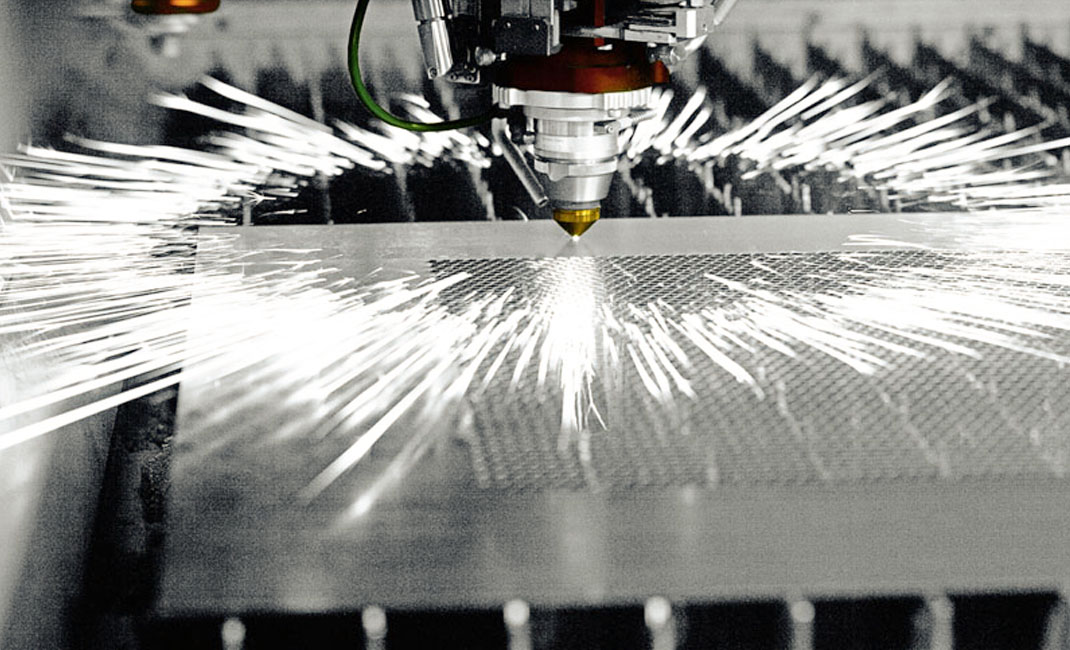

With our new laser system we can speed up the processing time for our products enormously. For example, we can now cut server rack doors in just 67 seconds instead of 120. The laser itself works at a speed of 60m/minute and can cut both complex contours and clean, precise edges. The completely automated loading and unloading also helps to reduce production times. By investing in this second laser system we have expanded our capacity to meet customers’ requirements.

Quick, clean, safe – expensive?

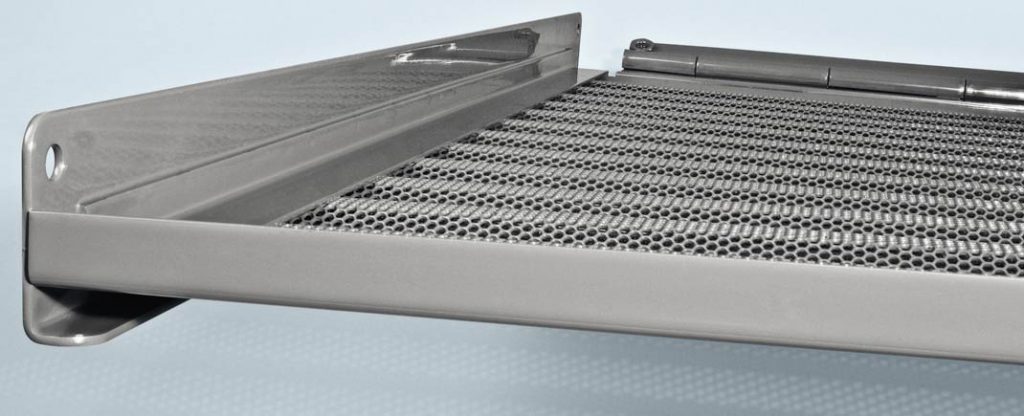

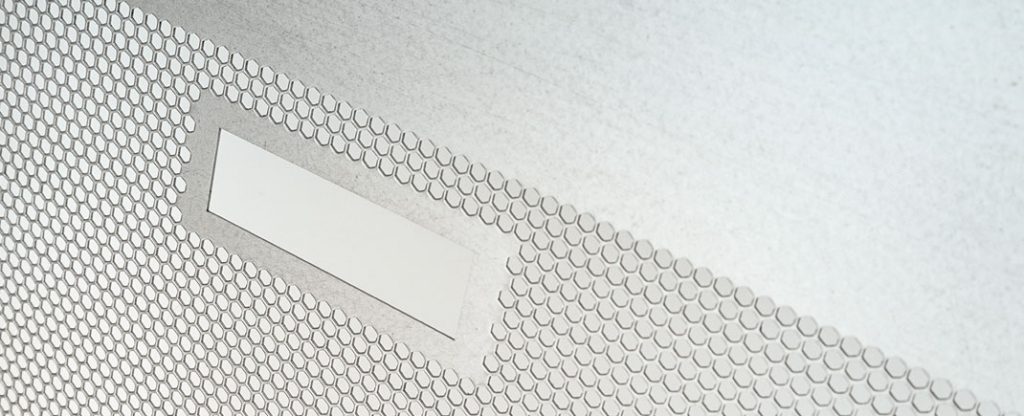

The latest fibre lasers are quick, clean and safe. However, procuring them involves a big investment. With our new system the transport fibre and focusing head generate a beam that achieves an impressive cutting speed of over 60 m/min. The €1 million investment is worthwhile for us and our customers. Using fibre laser systems is so much more energy-efficient. During the warm-up phase, the fibre laser consumes practically no energy, and in standby mode, its energy consumption is minimal. Unlike punching, lasers do not incur tool production costs, which means that even small quantities can be produced inexpensively. This way we can not only offer our customers the fastest production process ever – we can also help to save the environment and reduce our energy costs as well. At Solvaro, we can cut out server rack doors, engine covers and cooling grilles from steel sheets with thicknesses of up to 3.0 mm and sizes up to approximately 1.5 m by 3.0 m. With the new system, we have reduced the cycle time for processing server rack doors from 120 seconds to 67 seconds. Put simply, this means that on a day with three shifts, we can cut out 1,300 server rack doors instead of only 720.

Increasing automation

Loading the laser system, removing the components and disposing of the waste material are the key elements of our system. To fully exploit the laser’s speed, an automatic workpiece exchange function is required. But our laser not only needs to be fed quickly: in the exchange phase, it is also important to prevent cut pieces from falling onto the plate that is being processed. This is avoided by using a sophisticated alternating table system. Our system takes up an area 154 square metres, including the safety fence. As we mostly cut perforated plates, we have built in a special feature. The components are positioned to perfectly maintain the required distance between the hole pattern and the cut edge.

The solution at a glance

- shortest processing times

- clean, precise cutting edges

- flexible processing of orders thanks to short set-up times and costs

- inexpensive processing even in the case of small quantities