Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

As soon as an aircraft takes off, everything on board has to withstand a great deal, from uplift, thrust and gravitational pull to air pressure and changes in temperature. Most of this generally goes unnoticed by us, the passengers, but the aircraft components are directly subjected to these extreme forces. They therefore have to be especially robust in order for them to reliably fulfil their purpose. We manufacture an array of components for major companies in the aviation industry, at all times meeting the especially high quality and safety requirements.

Not all materials are cleared for take-off

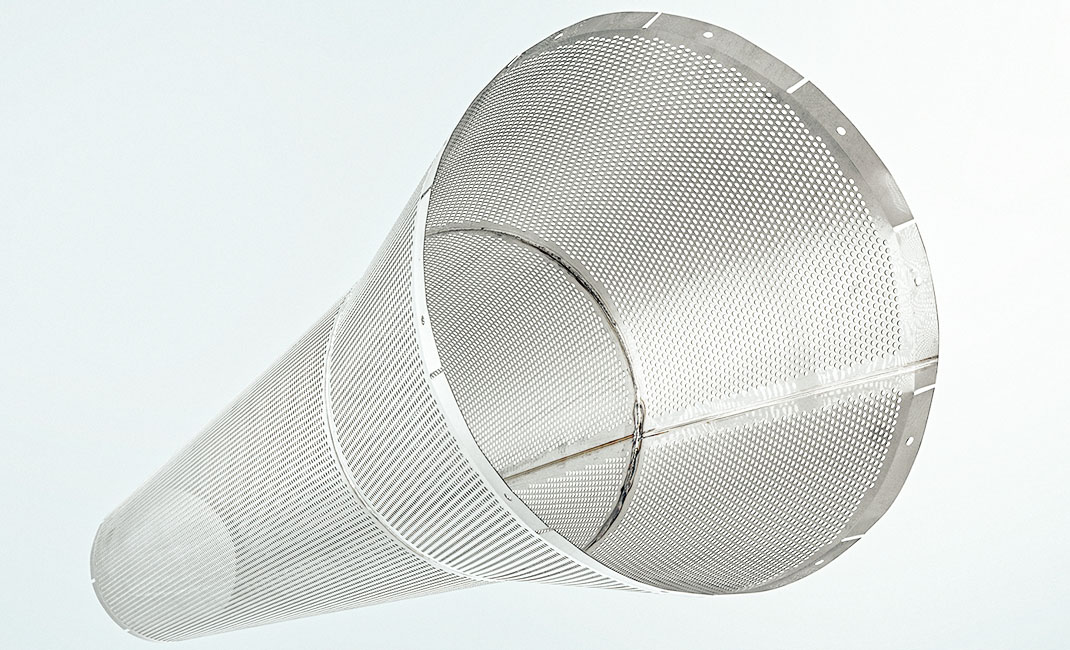

The lighter something is, the better it flies. The differences in the development and production of parts for the aviation industry compared with other sectors therefore usually start at the material selection stage. We use aluminium, titanium and stainless steel, depending on the specific area of application and the requirements. But one thing that all the materials have in common is that they have to comply with aviation standards certification. Because each and every component – be it a jet engine’s inner cladding or an air conditioning module – has to deliver absolute safety. In view of this, such parts are subject to very specific checks and can only be manufactured with exceptional care and the right expertise. This limits the purchasing department’s options in terms of its procurement sources, so careful planning right from the outset is essential.

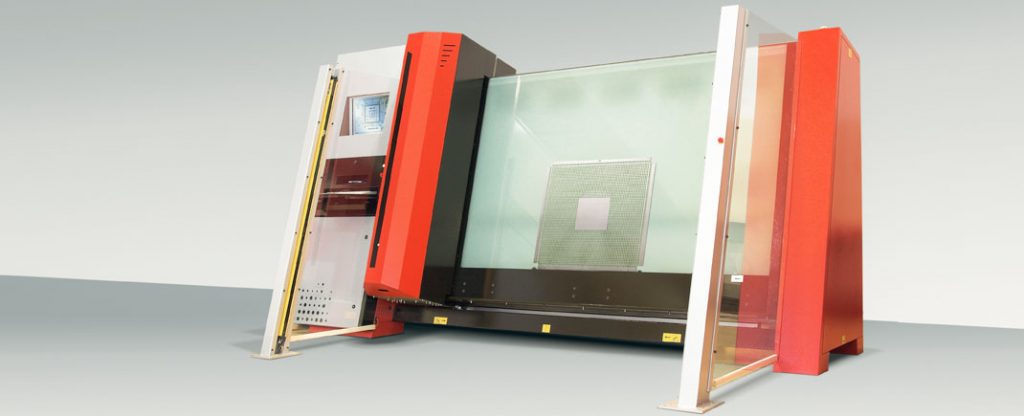

Our production approach is about getting things just right

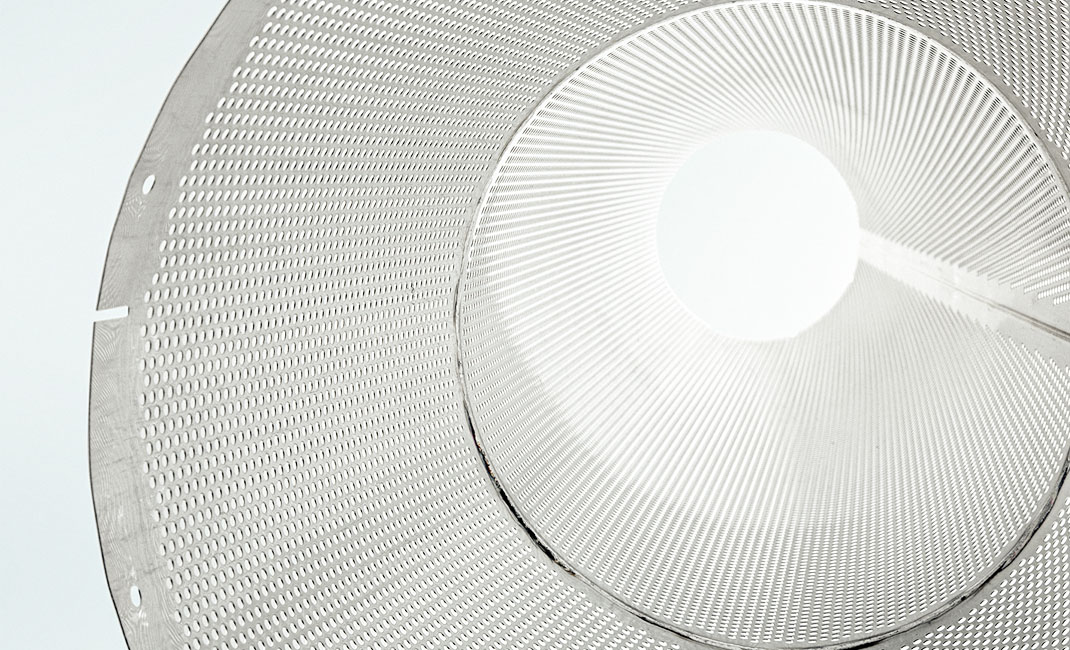

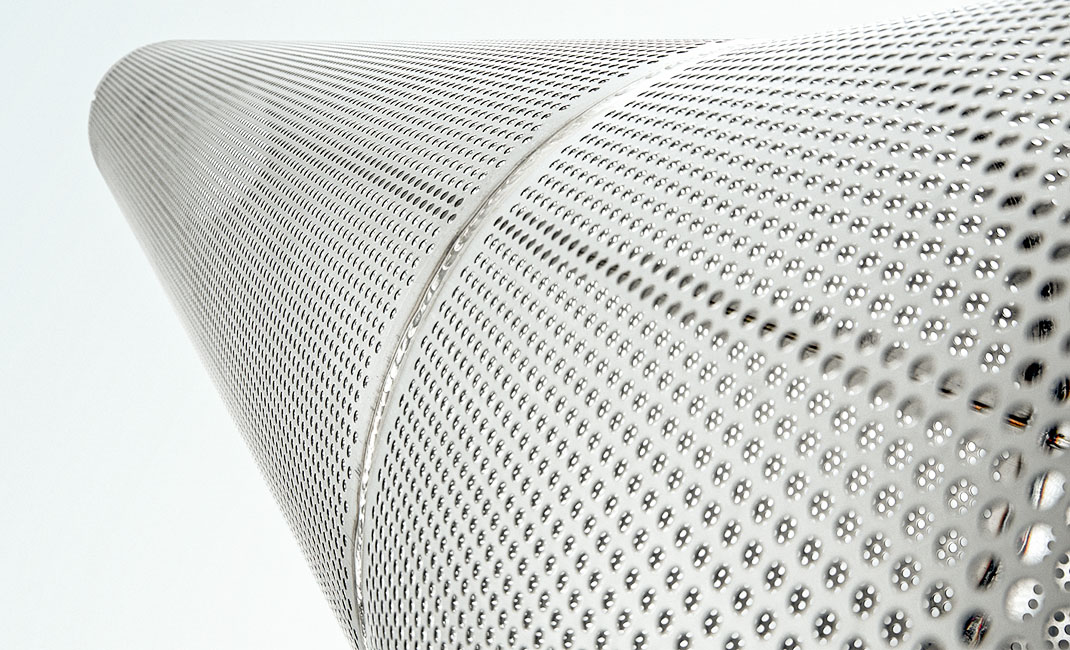

Special circumstances call for special measures. It therefore goes without saying that we build specially adapted facilities for the manufacture of special components. As an interesting example, our welder, who is certified for the aerospace sector, developed an entirely new piece of equipment for the complicated production of a unit comprising two cones. A complex process was therefore significantly simplified. Our experts draw on a wide array of manufacturing technologies in order to develop customer-specific solutions, ranging from perforation and bending, initial welding and edging to the final welding process. Carefully considered processes are used to develop the most cost-efficient solution. Upon request, the parts are also degreased and stretch-wrapped before the finished product is delivered to the customer.

The solution at a glance:

- Aviation parts made of aluminium, stainless steel and titanium

- Qualified purchasing of materials certified in accordance with aviation standards

- Special customer-specific production facilities

- Customer-specific degreasing and stretch-wrapping