Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

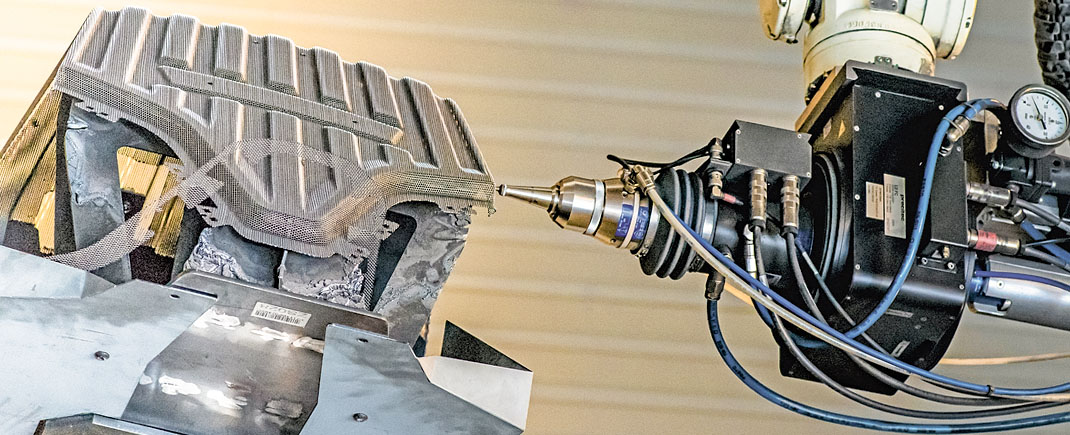

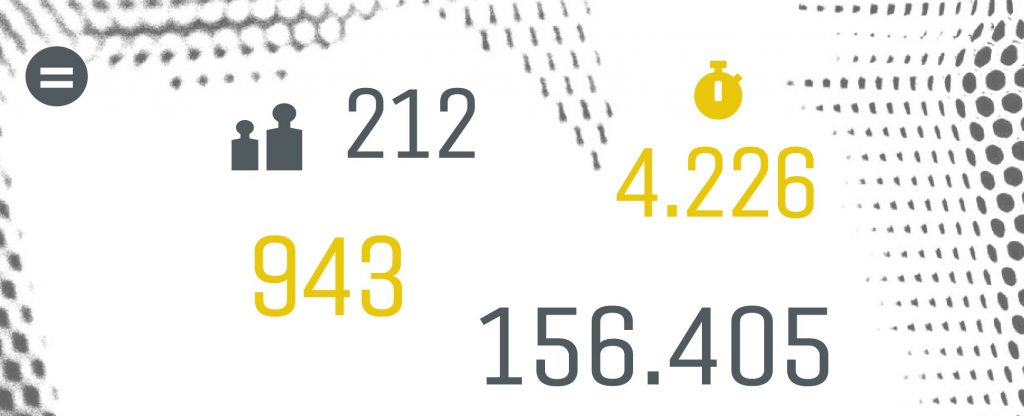

Our 3D laser machine is fast, flexible and highly accurate as it puts deep-drawn parts into the relevant shape. Thanks to its high cutting speed, it can create the right contours on up to 300 components per shift. The machine is helped by three robots which work together in perfect harmony and without stopping. Set-up times are short, and there is no need for expensive cutting tools. This is particularly important for small and medium-sized production series.

Series production without reworking

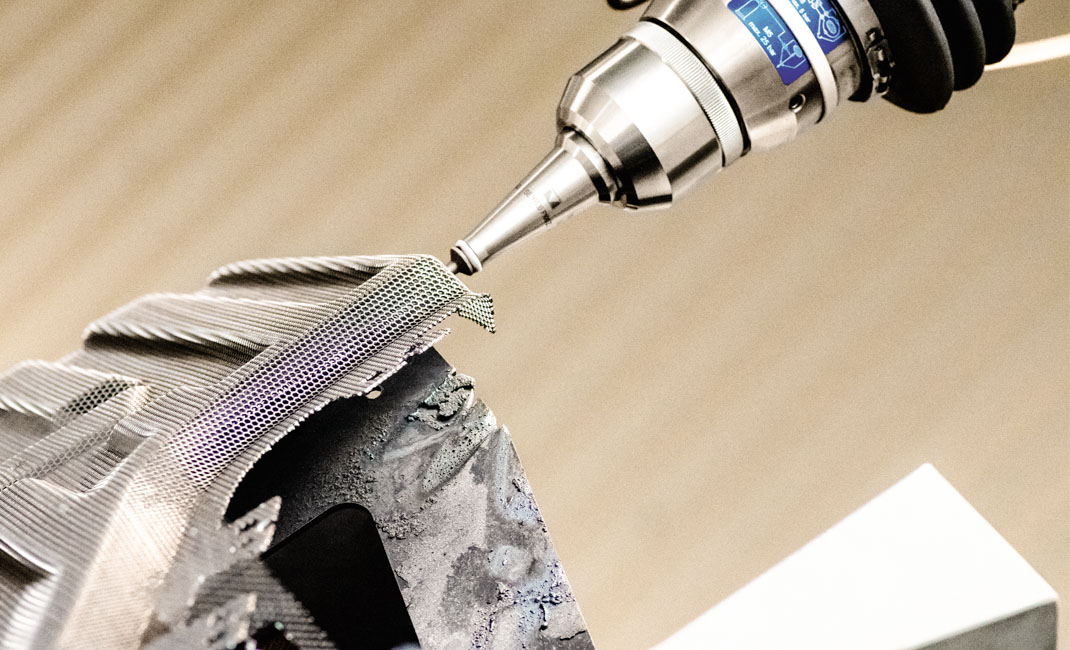

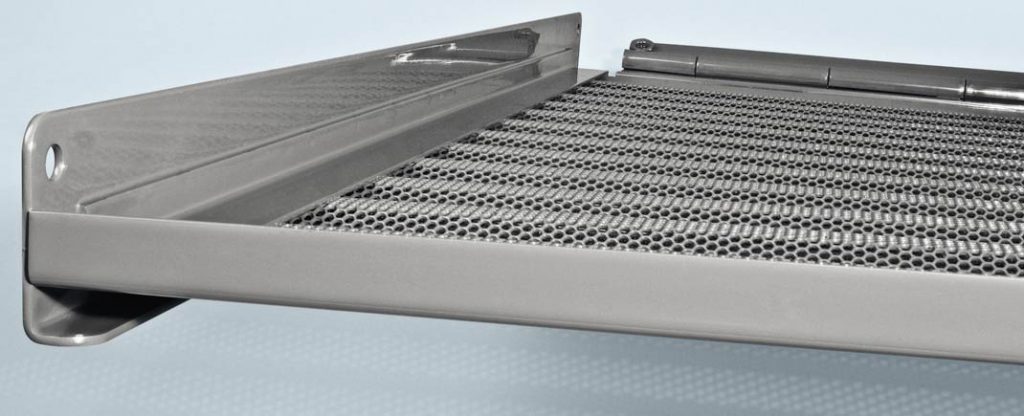

The processes on our 3D laser machine are not only extremely fast, but also highly reliable, so that series production requires no corrective work at all. This is of course essential for componentry. Reliable and accurate execution ensures that, when the parts are joined together, they will fit perfectly. The machine is used, for instance, for the components of ventilation screens in the new Kubota M7-171 tractor. A plant was set up especially for its production in Belgium, and so it went without saying that we, too, should use state-of-the-art engineering for this powerful Japanese company. Our 3D laser machine, which is 100 square metres in size, cuts components at a high level of accuracy, within a millimetre and without using cutting tools. Not only does it save costs, but the set-up can also be changed fast and flexibly for other types of components.

It’s the combination that matters

The system largely owes its amazing speed to three Kawasaki robots. They’re the ones that make it possible to load the machine without stopping it. Once a component is clamped into place, it can be tackled from any conceivable angle. Flexibility is increased even further by a movable cutting head. In fact, it moves around so swiftly and delicately that it can even cope with very short operational stages, such as cutting holes – without requiring the robots to move. Thanks to a series of cameras, the entire process is continually supervised live by an operator behind a protective wall.

The solution at a glance

- One-hundred-square-metre 3D laser system

- Fast, flexible and accurate cutting of deep-drawn components

- No need for tooling costs

- Economical, even for small quantities