Did we spark your interest? Then sign up for the SOLVARO newsletter and benefit from further knowledge on customised solutions regarding all things metal.

Server cabinet manufacturers struggle every day with tension levels in perforated sheets, problems with automated manufacture and warping of doors. But we have solutions to these problems. SOLVARO technicians apply the whole range of their experience to these issues. Orders that have been finished are carefully examined, raw material factory certificates are checked and technicians from the mills are closely involved in the whole process.

The result is that SOLVARO not only expects the highest standards from itself, but also from its raw material suppliers. The first step is to test any sample materials to see how they withstand the manufacturing process. If – and only if – they fulfil our requirements insofar as specifications and flatness are concerned, we then cooperate further with those suppliers.

Fine Adjustments

Once the raw material enters the manufacturing process, the extensive SOLVARO tool know-how takes effect. Tool preparation units ensure optimal cutting and accurate stamping. To produce perforations with an open area of 80 % and the lowest levels of tension, tool settings of the highest standard are required. In order to guarantee that requirements regarding flatness are fulfilled, our straightening machines are set to the highest levels of accuracy, ensuring excellent precision.

Consistent Quality

Regular checks, combined with cutting-edge measuring technology, serve to maintain tight tolerances and guarantee the consistently high level of quality expected from SOLVARO.

Call us on + 49 (0)7021 8048-102 and talk to our technical staff. We are certain that we’ll be able to find the perfect metal solution for you too.

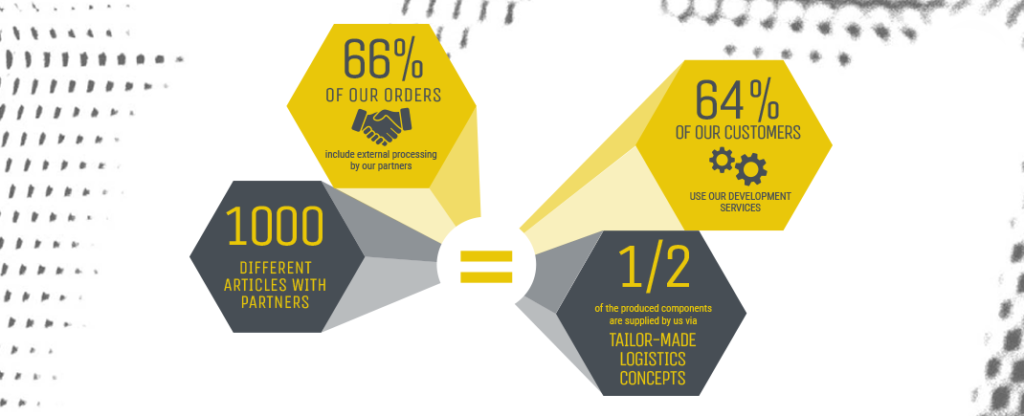

SOLVARO Performance at a glance

- Optimal flatness of perforated sheets

- Hexagonal perforations with open area of 80 %

- Highest level of precision thanks to special raw material specifications and long-standing tool know-how

- Consistent quality thanks to regular checks and cutting-edge measuring technology